Introduction

Are you familiar with hydraulic cylinders? They are mechanical actuators that are used to give unidirectional force through a unidirectional stroke. Put simply, they move things. Hydraulic cylinders are used in a wide variety of applications, ranging from construction and manufacturing to aerospace and healthcare. A supplier that provides high-quality hydraulic cylinders is critical to ensuring consistent operation and avoiding costly downtime. When choosing a supplier, consider factors such as reputation, quality assurance, price, and customer service. It’s important to find a supplier that can meet your specific needs, whether you require customizations or quick turnaround times. Let’s dive into the world of hydraulic cylinders and find the perfect supplier for you.

Types of hydraulic cylinders

When it comes to hydraulic cylinders, there are several types available in the market. Single-acting cylinders are the simplest and least expensive, as they use fluid pressure to extend the piston in only one direction, with the load helping to retract it. On the other hand, double-acting cylinders can extend and retract using fluid pressure, making them more versatile. Telescopic cylinders are designed to provide an exceptionally long stroke length in a compact package, while rodless cylinders use an external carriage to support the load and are ideal for applications with limited space. Finally, tandem cylinders come with two pistons working in opposite directions, allowing for a strong lifting capacity. With so many types of hydraulic cylinders to choose from, it’s important to consider which one is suitable for your specific application. Each type has its own strengths and limitations, so it’s worthwhile to consult with a knowledgeable supplier to ensure you get the right product for your needs.

Components of a hydraulic cylinder

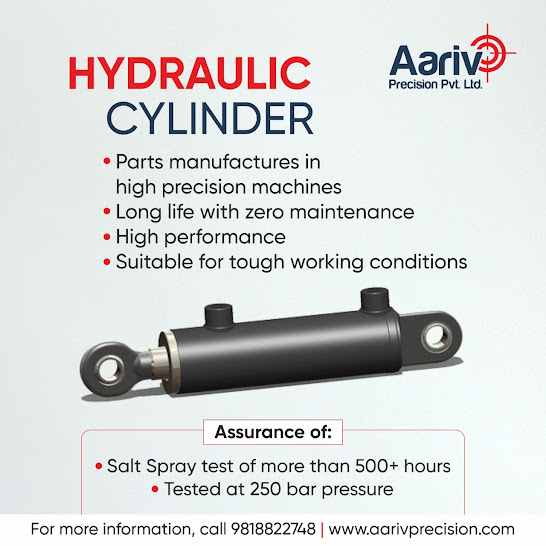

Let’s dive straight into the components of a hydraulic cylinder! The cylinder barrel is the main cylindrical body that holds the pressure and force generated by the hydraulic fluid. It’s usually made of high-quality steel or iron. The piston, on the other hand, is a disc that moves back and forth inside the barrel. It helps to convert the pressure of the hydraulic fluid into linear force. The piston rod attaches the piston to the end cap and extends out of the cylinder to transmit the force generated within the cylinder. The end caps, often made of steel, are attached to the barrel’s ends and help to retain the hydraulic fluid within the cylinder. Finally, the seals prevent the hydraulic fluid from leaking out of the cylinder, protecting the entire system’s efficiency. It can be quite challenging to understand the various components of a hydraulic cylinder, but that’s where an expert supplier comes in. A reliable supplier should guide you through all the components and specifications to ensure that you’re making the right choice for your application. Nevertheless, it’s worth noting that hydraulic cylinders are quite versatile, and you can customise them for specific applications.

Hydraulic cylinder specifications

When it comes to hydraulic cylinder specifications, there are several key points you need to consider before making a purchase. The bore size, stroke length, maximum operating pressure, mounting style, and materials are all crucial factors that will affect the performance and durability of your hydraulic cylinder. The bore size and stroke length determine the volume of fluid that can be displaced by the cylinder, which ultimately affects the force the cylinder can produce. The maximum operating pressure is the maximum amount of pressure the cylinder can withstand without failing. The mounting style refers to how the cylinder will be attached to the equipment and the orientation of the ports. Finally, the materials used in the construction of the cylinder can impact its resistance to wear, corrosion, and heat. When selecting a hydraulic cylinder, it’s important to ensure that all of these specifications meet the requirements of your particular application. You don’t want to end up with a cylinder that can’t produce enough force or is prone to failure due to pressure overload. Additionally, make sure to consider the supplier’s reputation for quality and reliability. You want a supplier who can provide you with customized options if needed, and who offers competitive pricing and reasonable lead times. A supplier who provides excellent customer support is also a bonus. By taking the time to carefully consider the specifications of your hydraulic cylinder and choosing a reputable supplier, you can ensure that your equipment will perform reliably and effectively.

Factors to consider when choosing a hydraulic cylinder supplier

When it comes to choosing a hydraulic cylinder supplier, there are a few key factors to consider. Firstly, experience and reputation can give you a good indication of the quality of the supplier’s products and services. You want to work with a supplier who has been around for a while and has a proven track record of providing reliable hydraulic cylinders. Quality assurance is also important. You want to make sure that the supplier has strict quality control processes in place to ensure that their products meet the necessary standards and specifications. This will give you peace of mind that the hydraulic cylinder you receive is safe and reliable. Customizability is another factor to consider. You want to work with a supplier who can provide customized solutions that meet your specific needs and requirements. This can help you to optimize your hydraulic system and improve its performance. Of course, price and lead time are important considerations as well. You want to work with a supplier who offers competitive pricing and can deliver your hydraulic cylinders in a timely manner. Finally, customer support and service are crucial. You want to work with a supplier who is responsive and provides excellent customer service, so that you can get the help you need when you need it. Overall, choosing the right hydraulic cylinder supplier is key to ensuring the success of your hydraulic system.

Top hydraulic cylinder suppliers

Let’s face it – finding the right hydraulic cylinder supplier can be a daunting task. With so many suppliers out there, how do you know which one to choose? Here are some top suppliers who we believe offer great products and services. Company A is a leading supplier of hydraulic cylinders, offering a wide range of products to meet your needs. They specialize in custom cylinder solutions, ensuring that your cylinder is tailored to your exact specifications. Their products are made with the highest quality materials, ensuring that they’re built to last. Company B is another top supplier, offering a variety of hydraulic cylinder solutions for a range of applications. Their products are known for their durability and reliability, making them a popular choice among customers. With a commitment to quality and customer service, they’re a great option if you’re looking for a reliable hydraulic cylinder supplier. Finally, Company C is a well-respected supplier of hydraulic cylinders, offering a range of products that are designed to meet the needs of a variety of industries. They specialize in custom cylinder solutions, ensuring that their products are tailored to your exact specifications. With a dedication to quality and customer service, they’re a great option if you’re looking for a hydraulic cylinder supplier who will work with you to find the perfect solution for your needs. Overall, when it comes to finding the right hydraulic cylinder supplier, it’s important to consider factors like experience, reputation, and product offerings. These top suppliers offer great products and services, making them a good place to start your search.

Conclusion

The importance of getting the right hydraulic cylinder specification and supplier cannot be overstated. A high-quality cylinder can improve the efficiency and longevity of your equipment, while a poor one can be a costly mistake. It’s crucial to factor in various specifications, such as bore size, stroke length, and mounting styles. Additionally, experience, reputation, and customizability are essential when choosing a supplier. Remember, the lowest price may not always be the best choice. Keep in mind that quality assurance, customer support, and service are paramount. Take the time to research and find reputable suppliers with an excellent track record.

No comments:

Post a Comment